Efficient Water and Wastewater Treatment for Iron & Steel Industries Using ETP, STP, WTP, WWTP, RO, and Recycling Solutions

India's iron and steel sector is one of the most vital pillars of industrial development. Ranked among the top producers globally, the industry supplies essential raw materials for infrastructure, automobiles, railways, and heavy machinery. It is deeply integrated into the nation's growth story.

Maharashtra, with its robust industrial base and connectivity, hosts several large-scale steel plants. The presence of industrial zones like Pune, Nagpur, and Mumbai further supports steel manufacturing. However, these operations consume huge volumes of water and generate wastewater that needs careful handling for sustainable operations.

Water is essential for cooling, dust suppression, descaling, and other steelmaking operations.

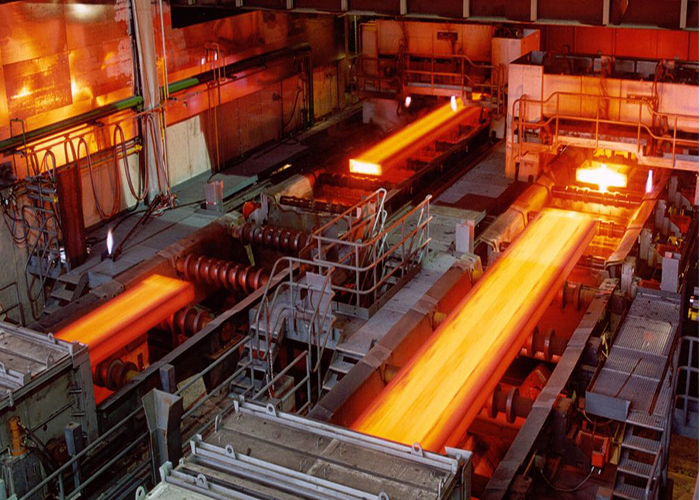

Steel plants require large quantities of water for cooling molten metal, dust control, and cleaning. In blast furnaces, water plays a crucial role in temperature regulation and process stability. It's also used in rolling mills, pickling lines, and hydraulic operations.

Besides direct industrial use, water is also necessary for auxiliary systems like boilers, air conditioning, and workforce utilities. In total, thousands of cubic meters of water may be used daily, emphasizing the importance of conservation, treatment, and reuse.

Rolling, pickling, cooling towers, and slag processing create significant wastewater streams.

Key operations in steel plants generate wastewater at various stages. Rolling mills release scale-laden water while pickling processes involve acidic wastewater due to hydrochloric or sulfuric acid use. Cooling towers generate blowdown, and slag processing units produce rinse water and leachate.

"In the iron and steel industry, water is as vital as ore. Every drop counts, from cooling to cleaning. Conserving and recycling water ensures sustainable production, protects natural resources, and meets environmental norms. A smart water management system is the foundation for long-term industrial success."

These streams often contain oils, heavy metals, solids, and chemical residues. Without treatment, they can severely impact groundwater and surface water ecosystems. Therefore, managing these effluents with an effective treatment system is not just a regulatory necessity but an environmental responsibility.

Oily water, acidic rinses, scale-laden flows, and chemical residues define steel plant effluent.

The nature of wastewater in steel industries varies based on the processes. It often contains oil, grease, suspended solids, heavy metals like zinc, chromium, and nickel, and high-temperature effluents. Acidic rinses from pickling lines contain low pH levels of dissolved iron and other harmful elements.

Other pollutants include phosphates, ammonia, and cyanide, depending on the specific treatments used in surface finishing. Proper segregation and treatment of these waste streams are crucial to reduce toxicity, corrosion, and environmental hazards.

Physical, chemical, and biological methods are used in combination to treat steel plant effluent.

Treatment of steel plant wastewater typically begins with oil and grease separation through skimmers or floatation. Sedimentation and filtration help remove suspended solids and scale. Neutralization tanks adjust pH levels before chemical dosing removes heavy metals.

Biological treatment may be applied for organics, followed by tertiary processes like sand filtration, activated carbon, or even membrane filtration. A well-structured Effluent Treatment Plant (ETP) ensures that treated water meets CPCB norms and is safe for discharge or reuse within the facility.

Modern plants use RO, ZLD, and automation to optimize water use and recycling.

Today's steel industries are adopting advanced technologies to improve water efficiency. Zero Liquid Discharge (ZLD) systems are increasingly used to recycle nearly all wastewater. Reverse Osmosis (RO) and Ultra Filtration (UF) systems help purify water for reuse in cooling and washing processes.

Automation and real-time monitoring systems help manage flows, reduce wastage, and ensure plant efficiency. These technologies not only reduce environmental impact but also lower operational costs by minimizing freshwater intake and waste disposal fees.

We offer customized ETP, RO, and WTP systems for sustainable steel manufacturing solutions.

We specialize in designing and implementing water treatment systems tailored to the unique challenges of iron and steel factories. Our expertise spans Effluent Treatment Plants (ETPs), Water Treatment Plants (WTPs), Reverse Osmosis (RO) systems, and Zero Liquid Discharge (ZLD) setups.

Our approach starts with a detailed site study and effluent analysis, followed by turnkey project execution—including installation, automation, and long-term support. Whether it's pollution control compliance or water recycling goals, we help steel units reduce waste, reuse water, and operate more sustainably.

Conclusion: Effective Water Management is Key to Sustainable Steel Industry Operations

Conclusion: Effective Water Management is Key to Sustainable Steel Industry Operations

Water is a critical input in steel production, but it must be managed responsibly. As environmental regulations tighten and water scarcity becomes a challenge, industries must adopt efficient wastewater treatment and recycling solutions.

Water is a critical input in steel production, but it must be managed responsibly. As environmental regulations tighten and water scarcity becomes a challenge, industries must adopt efficient wastewater treatment and recycling solutions.